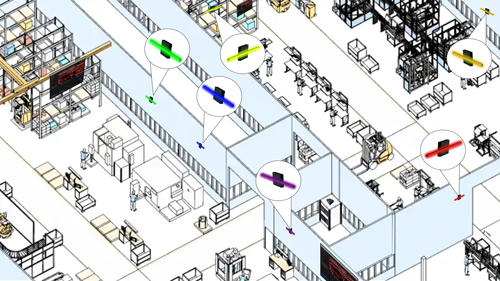

Lumalert – an IP visual alert solution for the factory floor

Lumalert is an industrial-strength IP-connected LED fixture that is part of a visual communication system on the factory floor, utilizing standard ISO 3864 alert colors and effects. The system enhances situational awareness, reduces response times, and minimizes reliance on audible alarms (which can be drowned out by machinery noise) or manual checks. Broadcast IP commands can trigger preset alerts to all, a group zone, or individual fixtures. Driven by Ethernet PoE power, Lumalert units can be surface-mounted or mounted onto standard 2-gang boxes.

For example, Lumalert fixtures across the factory could indicate:

- Green – machine working properly

- Blue - preventative maintenance due soon

- Red – Machine/Robot offline

- Yellow - backlog in unit testing

- Orange - parts inventory running low

- Purple – quality control issue

- Cyan – Unsafe conditions such as high noise, air quality, and temperature

Taking Control

The Lumalert fixture is comprised of an 18” high-output color LED bar. The compact base mounts with 2 screws to a surface or a 2-gang electrical box. Inside the base is an RJ45 Ethernet connector, RS-232 port for local programming, closure inputs for local preset triggering, and a 12V power input (if needed).

The unit operates over an Ethernet network as a DHCP device and can receive up to 7ma of POE power. Each Lumalert is assigned a device number set from onboard DIP switches and hosts a Web page that be accessed over the network through free LA Toolbox software for setup and monitoring. The device number is set to one of 15 device zone groups.

Commands are broadcast through the network, then the fixtures respond to a global address, a zone number, or an individual device number. An installer can define the color presets for the system into a single Lumalert, then send the settings to all connected units.

AV Integrators are uniquely qualified to create an interactive visual signaling system. A custom control solution adds the ability to receive inputs from touch screens, assembly machines and robots, security, and environmental systems. From that data, a control system can send Lumalert preset commands across the network.

ISO 3864 Alert Standards

This standard states colors and effects for alerts in manufacturing spaces. While most sites won’t use all the available options, the standard allows consistency of alerts for management and workers in the industry.

Safety and Emergency Alerts

These prioritize worker protection and rapid response to hazards, which are common in factories involving heavy machinery, chemicals, or high-risk processes.

- Red (flashing) - Emergency Stop or Hazard Detection. Indicates an immediate danger, such as a machine malfunction, chemical spill, or detected gas leak. Workers can quickly evacuate or shut down operations, reducing injury risks.

- Alternating Red/White - Evacuation or Fire Alert. Signals the need to clear the area due to fire, explosion risk, or structural failure. This ensures coordinated evacuation without confusion.

- Amber (flashing) Personal Injury or Medical Emergency. Alerts nearby staff to assist an injured worker, perhaps integrated with wearable sensors. It helps summon first aid teams promptly.

Operational and Machine Status Alerts

Factories often have multiple machines running simultaneously, so visual indicators help monitor performance without constant manual oversight.

- Red – Machine Downtime or Breakdown. Notifies maintenance teams of a stopped or faulty machine, minimizing production delays. For example, if a conveyor belt jams, the light changes to alert operators.

- Blue - Preventive Maintenance Needed. Warns that a machine is approaching a service interval (e.g., based on runtime hours or sensor data). This prevents unexpected failures and extends equipment life.

- Green - Normal Operation. Confirms everything is running smoothly, allowing workers to focus elsewhere. A shift to yellow could indicate minor issues like overheating before they escalate.

Production and Workflow Alerts

These optimize throughput, quality, and efficiency on assembly lines or production zones.

- Yellow - Production Slowdown or Bottleneck. Highlights delays in a specific section, such as a backlog at quality inspection. Supervisors can reallocate resources to resolve it quickly.

- Purple - Quality Control Issue. Flags defective products or process deviations (e.g., via integrated cameras or sensors). This prevents faulty items from advancing, reducing waste and rework.

- White or Green flashing - Target Achievement or Milestone. Celebrates meeting quotas or completing a batch, boosting morale and signaling the start of the next phase.

Inventory and Resource Alerts

In just-in-time manufacturing, timely alerts prevent stockouts or overstocking.

- Orange - Low Inventory or Supply Shortage. Indicates when raw materials, parts, or tools are running low (triggered by inventory sensors). Workers can reorder or switch tasks to avoid halts.

- Yellow flashing - Waste or Overflow Alert. Warns of overfilled bins or excessive scrap buildup, promoting lean practices and maintaining a clean workspace.

Environmental and Compliance Alerts

Factories must monitor conditions to comply with regulations and ensure worker comfort.

- Cyan - Environmental Hazard. Signals unsafe conditions like high noise levels, poor air quality, or extreme temperatures/humidity. This prompts ventilation adjustments or breaks.

- White flashing - Shift Change or Break Time. Reminds workers of scheduled breaks, shift ends, or handovers, helping maintain fatigue management and compliance with labor laws.